There are various plastic production methods to choose from, and you will find wide ranges regarding flexibility of shape, setup costs, costs per component part, finish time, and the scale of manufacturing the method allows. Widely used methods include CNC (computer numerical control) machining and vacuum formation, each of which serve distinct design and style and development needs. CNC, for example, has a medium level of freedom when it comes to the form, a finish period of less than a day, a moderate setup cost, high cost of individual components, and satisfies massive scale production. Vacuum formation, on the other hand, has a very limited freedom of form, only really suitable for developing basic shapes, and can feature a finish time of up to a month. Also, since there is a wide scope of CNC machines, from simple desktop technology, to much more highly developed pieces of equipment, the set-up price varies from low to high, and the price per component and the completion time are highly diverse, and dependent on the sophistication of the equipment.

CNC Machining

CNC machining is a computer controlled subtractive procedure, which eliminates material from plastic in an effort to create the desirable shape. The computer is high-tech, with the ability to transform a design into figures by using a computer assisted design computer software system. The numbers are competent to control the equipment to cut the required form. To setup, the machines require an intermediate step in the development and validation of tool paths. Once the machine is provided with the tool paths, the subtractive process is started. When the construction is finished, the component is cleansed, smoothed, and cut.

For low quantity plastic component applications that call for tight tolerances and shapes which are tough to mould, machining is appropriate. CNC machining boasts low to moderate initial costs, and can generate high quality plastic components with minimal finishing times. Even so, with increased product intricacy, the charge per component increases. Additionally, the process necessities tool access allowances, and specific designs, for instance those with spherical inner channels, are near-impossible to produce using CNC manufacturing.

Summary Of Vacuum Formation

Vacuum formation is a process during which plastic is warmed and moulded, usually working with a mould. The enormity and sophistication of vacuum-forming machines cover anything from low priced desktop equipment to state-of-the-art production equipment.

It can be suited to any task, ranging from custom designs to large-scale fabrication, considering the large array of machinery available and that automatization is an option if required. Nonetheless, there’s minimum freedom in the types of shape it can create, and is unfortunately only able to build parts with basic geometries. In comparison with other methods, tooling prices are low, given that vacuum formation only requires low forces and pressures. Commonly, for modest production sizes the moulds are constructed of 3D printed resin, or even plaster, and for greater production sizes more durable equipment made of metal is used.

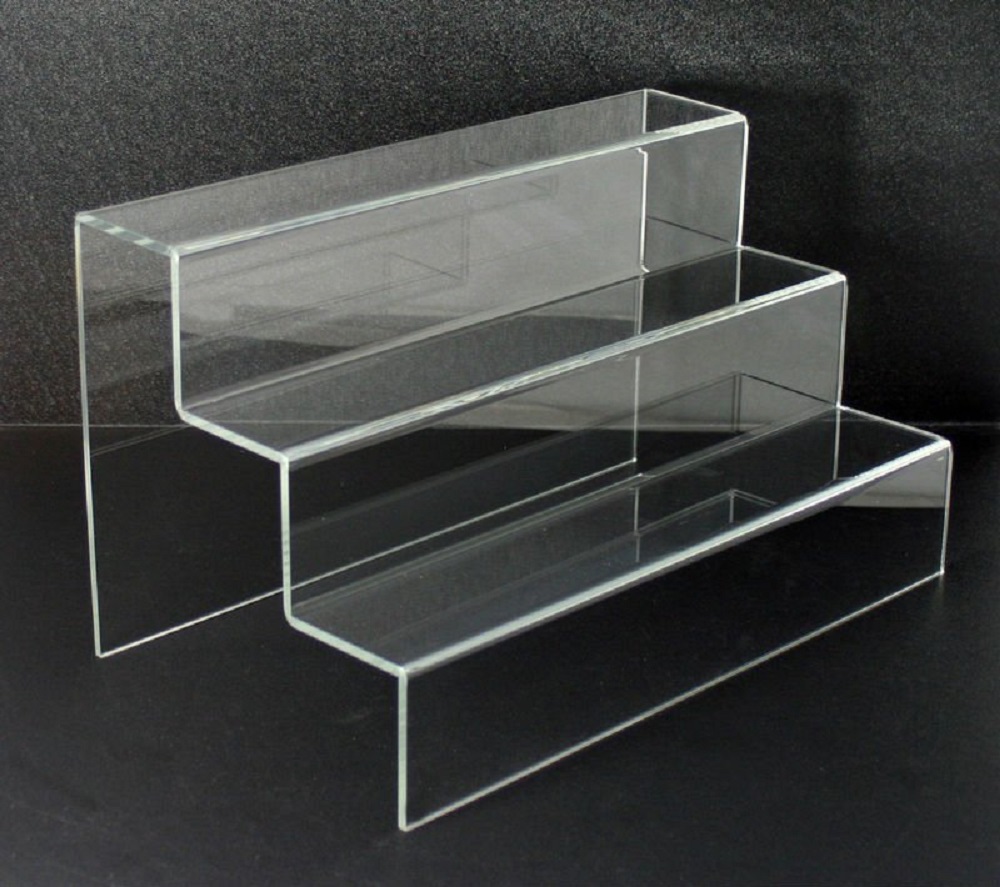

The manufacturing process commences with a sheet of plastic getting clamped and warmed until the plastic becomes mouldable. The plastic will then be put into the mould and chilled, and often fans as well as other chilling techniques are used in an effort to speed up the chilling process. The ultimate stage entails any excess plastic being removed. {Click here for details bespoke acrylic trays.You will find many thousands of websites with important info with regards to ‘acrylic moulding Uk’ this really one of the best websites perspex moulding.|{For those who are looking at more information associated with thermoforming plastic parts this specific page plastic prototype cost contains numerous more write-ups dealing with moulded plastic prototypes. The site plastic development offers quite a bit more information on the main topic of plastic moulding parts. There are several plastic moulding parts web sites in the UK, should you be looking to find out more or perhaps even pricing this page is an excellent kick off point